custom sunglass accessories factory bulk production

Oem

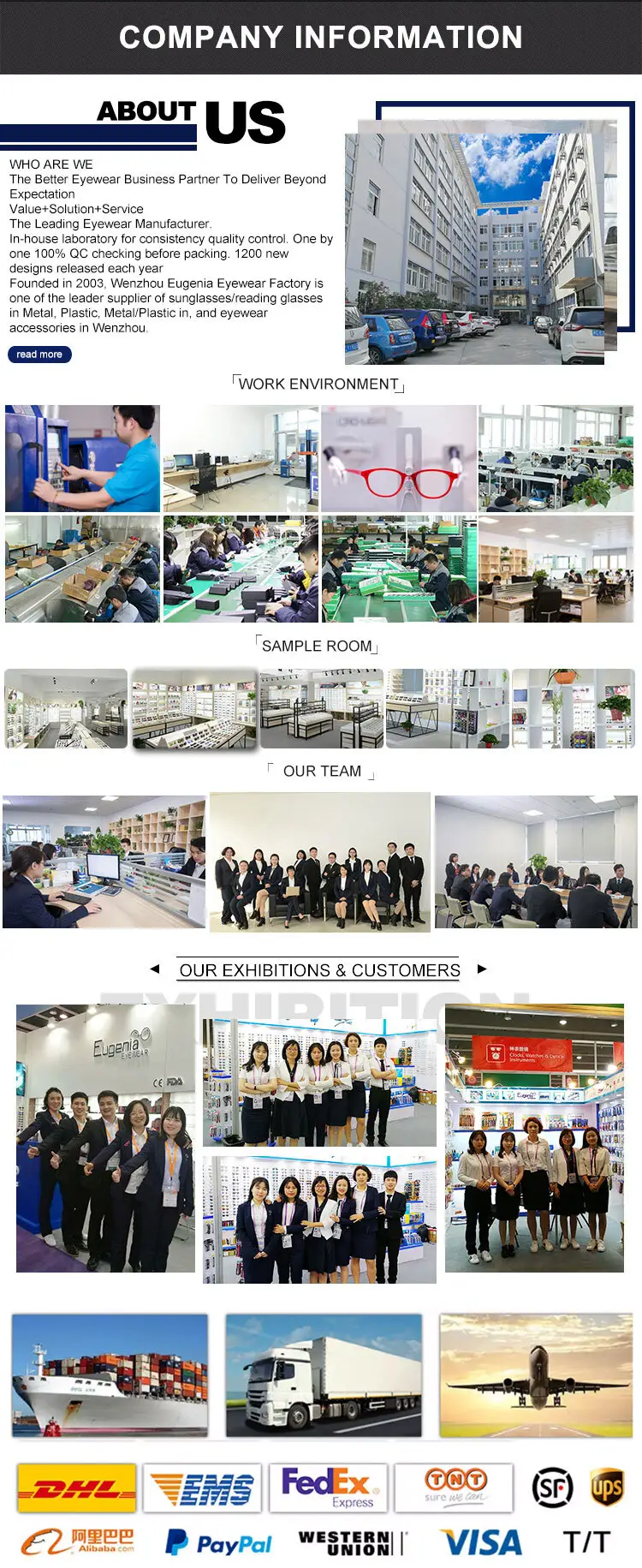

Company Information

FAQ

| Q: What's your MOQ? |

| A: 300PCS |

| Q: Do you accept OEM & ODM? |

| A: Of course, both OEM and ODM can be acceptable. |

| Q: May I have a sample to test quality before I place the order? How much the sample cost? |

| A: Sure ! |

| 1)For our ready design, free sample is available, but freight is required. |

| 2)For your design sample, both sample charge and freight are asked. |

| Q: How long for sample time? |

| A: It about takes 2-7days to prepare. |

| Q: What's the packing? |

| A: Usually is inner box+ outside carton, It can be packed as your requirement. |

| Q: What’s your payment term? |

| A: 1)Alibaba trade assurance. |

| 2) T/T, 30% deposit before producing, 70% balance payment against B/L copy. |

| 3) L/C at sight. |

| 4) Western union |

| Q: Do you have any certification? |

| A: Yes,We are BV audited factory, CE, SGS, EN71,EN12312, certifications are available. |

| Q: Do you have any cooperate experience with big wholesale or supermarket? |

| A: Yes,We have many big clients . Such as Solar Fashion and Walgreen in USA, |

| Especially, we cooperate with Wal-Mart for long term. |

Eugenia Eyewear Company Ltd. has abundant material resources for sunglasses manufacturers.

Eugenia Eyewear Company Ltd. has gathered a group of outstanding management talents and technical talents for sunglasses manufacturers.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

+86-15858887570

Operating hours

Monday - Friday(GMT+8): 8am - 5pm Saturday: 9am - 4pm

High quality product, professional service, being the core supplier in laser industry!

Shortcut links

Products

Contact us

Contact person: Kiki

Tel: +86 577 85622207

Wechat/Mobile: +86 15858887570

Address

No.115 Yucang east road, economy and technology development zone, Wenzhou city, Zhejiang province, China